ZhengYang Zhongke

Defense Wall Without Bullets

| Quantity: | |

|---|---|

8.Other Product Types

8.Other Product Types

This rapid deployment barrier system can help man make rapid response to emergencies by releasing concertina razor wire coils barrier. This long fence can prevent intrusion of terrorists, illegal protests, people who cross the border even a tank in battle field.

This rapid deployment barrier system can help man make rapid response to emergencies by releasing concertina razor wire coils barrier. This long fence can prevent intrusion of terrorists, illegal protests, people who cross the border even a tank in battle field.

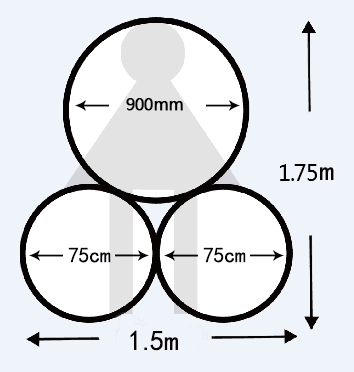

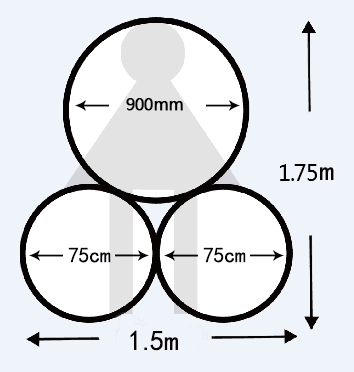

Height: 1.75m

Height: 1.75m

There are five stages of production process.

1. Steel Bar Arrangement. Workers use machines to cut the steel bars into desired shapes, according to the drawings.

2. Surface treatment ( 8 steps). It is to give the metal a reasonably hard, electrically non-conducting surface coating of insoluble phosphate, which is contiguous and highly adherent to the underlying metal, and is considerably more absorptive than the metal.

3. Welding and Assembly. During this stage, we effectively combine components by using CO2 welding, nut and bolt.

4. Paint. We paint for two times to make the trailer surface more smooth and uniform.

5. Assembly. It is easy to assemble all part following on the instruction.

6. Test. All rapid deployment trailer is tested to make sure there is no problem when being used.

7. Packaging. The trailer body is covered with camouflage clothing; triple-strand concertina razor wire is packaged with woven bag. Supporting iron form will be used to fixed the razor wire when transported.

There are five stages of production process.

1. Steel Bar Arrangement. Workers use machines to cut the steel bars into desired shapes, according to the drawings.

2. Surface treatment ( 8 steps). It is to give the metal a reasonably hard, electrically non-conducting surface coating of insoluble phosphate, which is contiguous and highly adherent to the underlying metal, and is considerably more absorptive than the metal.

3. Welding and Assembly. During this stage, we effectively combine components by using CO2 welding, nut and bolt.

4. Paint. We paint for two times to make the trailer surface more smooth and uniform.

5. Assembly. It is easy to assemble all part following on the instruction.

6. Test. All rapid deployment trailer is tested to make sure there is no problem when being used.

7. Packaging. The trailer body is covered with camouflage clothing; triple-strand concertina razor wire is packaged with woven bag. Supporting iron form will be used to fixed the razor wire when transported.